Structural Steel

Structural Steel: Products

Structural steel is integral to contemporary architecture and engineering, providing the framework for skyscrapers, bridges, and various infrastructure projects. At Midland Alloys Inc., we specialize in delivering high-quality structural steel solutions tailored to meet diverse construction needs. Our structural steel products are designed for strength, durability, and reliability, ensuring that every project stands the test of time.

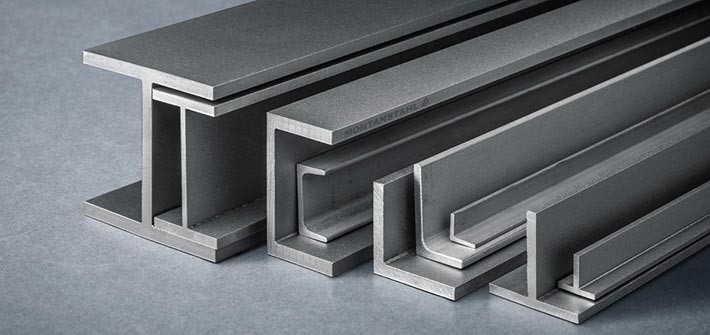

Our extensive range of structural steel products includes beams, columns, channels, angles, and plates. Each product is meticulously manufactured and tested to meet industry standards, offering superior load-bearing capacity and resistance to environmental stresses. Midland Alloys Inc. employs advanced technology and rigorous quality control processes to ensure that our structural steel meets the highest standards of performance and safety.

Types of Structural Steel

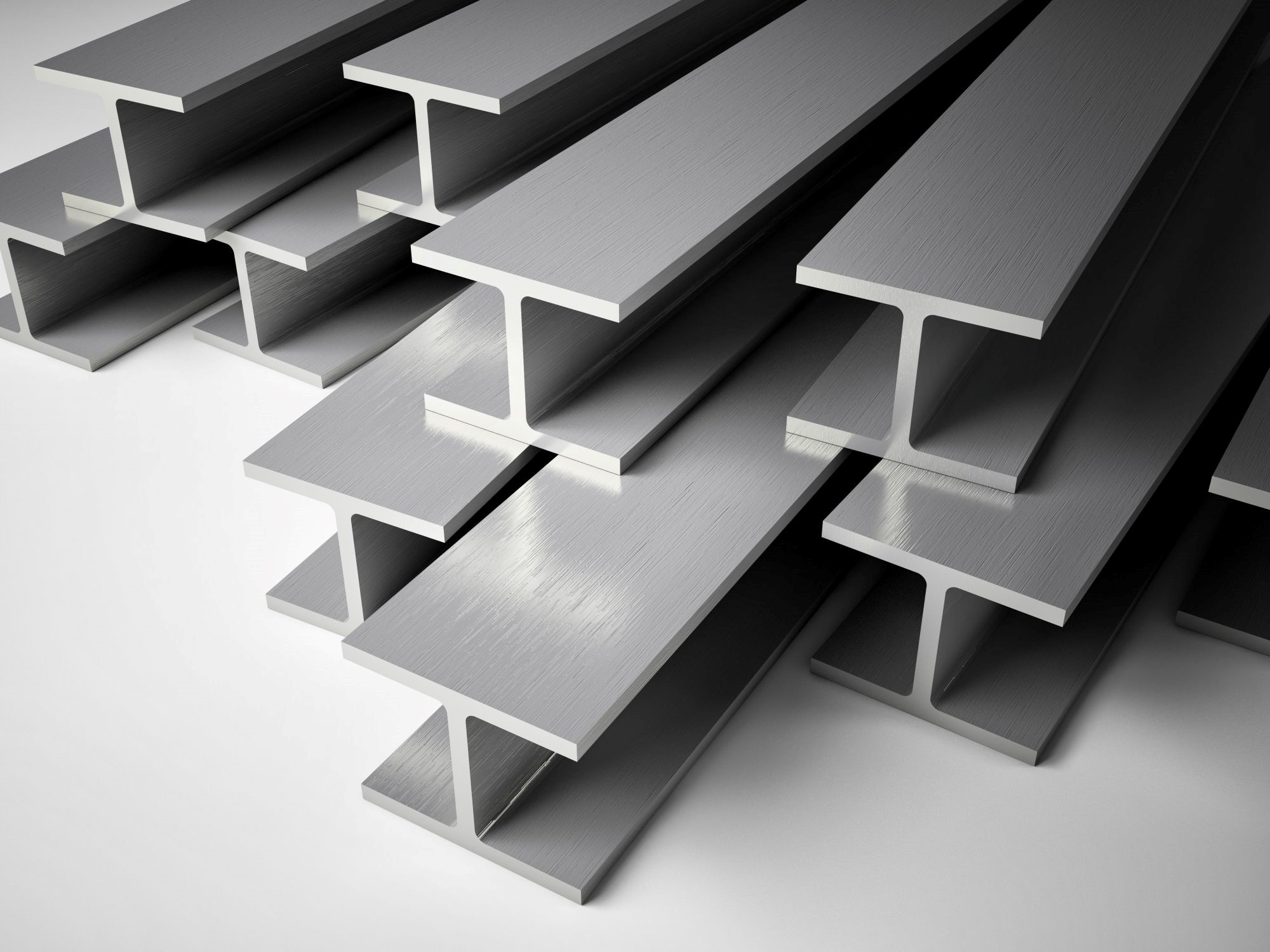

Beams

An MS Beam (Mild Steel Beam) is a critical structural component, primarily used to support heavy loads in buildings, bridges, and other large infrastructure projects. MS beams come in various types, shapes, and sizes, each designed for specific applications. These beams are designed to handle vertical gravitational forces and, in some cases, resist lateral forces such as wind and earthquakes.

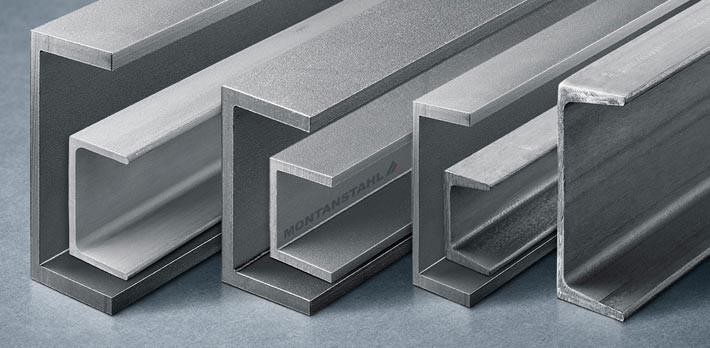

Channels

An MS (Mild Steel) Channel, often referred to as a C-Channel, is a structural steel product with a distinctive 'C' shape when viewed in cross-section. This shape consists of a wide, flat surface called the web and two horizontal surfaces known as flanges. The unique design of the MS Channel allows it to efficiently carry horizontal gravitational forces, providing essential support in various construction and engineering applications.

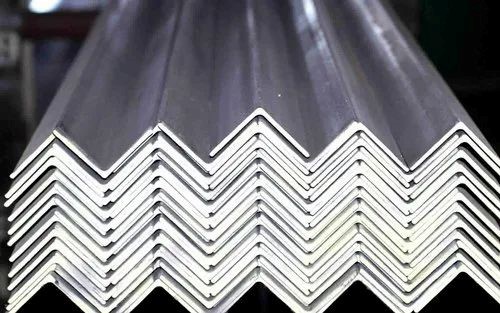

Angles

MS (Mild Steel) Angles are structural steel products that are extensively used in a variety of construction, engineering, and industrial applications. These angles are characterized by their L-shaped cross-section, making them ideal for providing structural support and stability in building frameworks and machinery. The "L" shape consists of two flat surfaces, referred to as legs, which can be of equal or unequal lengths.

Blooms

Steel blooms are fundamental products in the steel industry, known for their versatility, strength, and durability. These semi-finished steel products are typically produced through the continuous casting process and are further processed to create various finished steel products. Steel blooms come in a range of sizes and shapes and are used in various industries, including construction, automotive, manufacturing, and more. Their high tensile strength and excellent mechanical properties make them ideal for demanding applications. Additionally, steel blooms can be further processed to improve their properties, such as through heat treatment or coating, enhancing their performance and lifespan.

Billets

Steel billets are crucial semi-finished products in the steel industry, valued for their strength, versatility, and durability. Produced through processes like continuous casting or hot rolling, steel billets serve as the starting material for manufacturing a wide range of steel products. They come in various sizes and shapes, including square and rectangular cross-sections, and are used in diverse industries such as construction, automotive, and manufacturing. Their exceptional mechanical properties, including high tensile strength and good machinability, make them suitable for producing components that need to withstand significant stresses. Steel billets are often subjected to additional processing to enhance their characteristics, such as forging or heat treatment, to meet specific application requirements.

Applications of Structural Steel

- Buildings

- Bridges

- Infrastructure

- Industrial Facilities

- Renovations

- Civil Engineering

- Environmental Protections

- Noise Abatement

- Ports

- Waterways & Watercourses

Material Used in Structural Steel

- Carbon Steel

- Alloy Steel

- Stainless Steel

- High-Strength Low-Alloy Steel (HSLA)

Structural Steel Quality Control

Quality control in structural steel manufacturing is crucial to ensure the material meets required specifications and performs effectively in construction applications. Here’s a comprehensive overview of the key aspects of quality control for structural steel:

1. Raw Material Inspection

- Material Certification: Verify certificates of the raw materials to ensure they comply with the relevant standards and specifications.

- Chemical Composition Testing: Analyse samples to confirm the chemical composition matches the specified standards (e.g., IS 2062, ASTM, EN, JIS, DIN).

2. Dimensional and Visual Inspection

- Dimensional Checks: Measure dimensions (thickness, width, length) of the steel products to ensure they meet the specified tolerances.

- Visual Inspection: Inspect for surface defects such as cracks, weld flaws, or inclusions that could affect performance.

3. Coating and Corrosion Protection

- Surface Preparation: Ensure proper surface preparation before applying coatings to ensure adhesion and effectiveness.

- Coating Inspection: Verify the quality and thickness of protective coatings, such as galvanizing or painting, to prevent corrosion.

4. Documentation and Traceability

- Material Test Certificates: Provide test reports that verify the steel's chemical and mechanical properties.

- Traceability: Maintain records that link the steel products to their production batches, including test results and quality control checks.

5. Final Inspection and Certification

- Pre-Delivery Inspection: Conduct a final inspection before delivery to ensure all quality requirements are met.

- Certification: Provide certifications that confirm compliance with relevant standards and specifications.

6. Continuous Improvement

- Feedback Mechanisms: Implement feedback loops to address quality issues and make improvements based on inspection results and customer feedback.

- Training and Development: Regularly train personnel in quality control procedures and industry standards to maintain high-quality production.

Structural Steel: Grades and Standards

For Angles: IS : 808 -1989

For Channels: IS : 808 - 1989 / IS : 3954 -1991

For Beams: DIN : 1025 - 1994 / IS : 12778 - 1989 / IS : 808 - 1989

For Angles: IS : 1852 - 1985

For Channels: IS : 1852 - 1985 / IS : 3954 - 1991

For Beams: DIN : 1025 - 1994 / IS : 12779 - 1989 / IS : 1852 - 1985

For Angles: IS : 2062 : E250 A - 2006

For Channels: IS : 2062 : E250 A - 2006

For Beams: 2062 : E250 A - 2006

Blooms: Mild Steel/Low, Medium & High Carbon Steel, Forging Quality

Billets: Mild Steel, Low, Medium & High Carbon, Spring Steel, High Mn & Forging Quality Steels.

Specifications

Structural: IS 2062 E250A - 2006

Forging / Bright Bar 20C 15, 27C 15, SAE 1524S, SAE 1524CR

Medium Carbon, High Mn Steel CK-45, EN8, EN8A, EN8D, EN9,SAE 1049, 35C8

SAE 1524, EN15B, 37C15, A 105, 40Cr4 etc

Spring Steel: 55Si7, 60Si7, 65Si7, SUP9, SUPl1 A, SUP10

Case Hardening Steels: 20MnCr5, 16MnCr5

IS – E250, E275, E300, E350, E410, E450 as per IS 2062

EN – S235, S275, S355, S420, S460 as per EN 10025:2019

ASTM as per ASTM A36, ASTM A572, ASTM A992

JIS – as per JIS G 3101, JIS A-3106

DIN – as per DIN EN 10025

Corrosion Resistant Steel as per IRSM 41-97

FIRE RESISTANT STEEL AS PER IS 15103 / A1077M

WEATHER RESISTANT STEEL AS PER IS 11587

STRUCTURAL STEEL FOR BUILDINGS AND STRUCTURES WITH

IMPROVED SEISMIC RESISTANCE as per IS 15962

AS/NZS 3671.1 Grade 300/300L0/300L15/ 350/ 350 L0/ 350 L15

Sections

- Universal Beam (UB) Section

- Universal Beam (UB) Section

- Universal Column (UC) Section

- IPE section

- IPE section

- HE Section

- HD section

- HD section

- W section

- Angle Section

- NPB Section

- WPB Section

- JSPL section

- Channel Section

- Australia New Zealand Standard Universal Beams

- Australia New Zealand Standard Equal Angles

- Australia New Zealand Standard Universal Columns