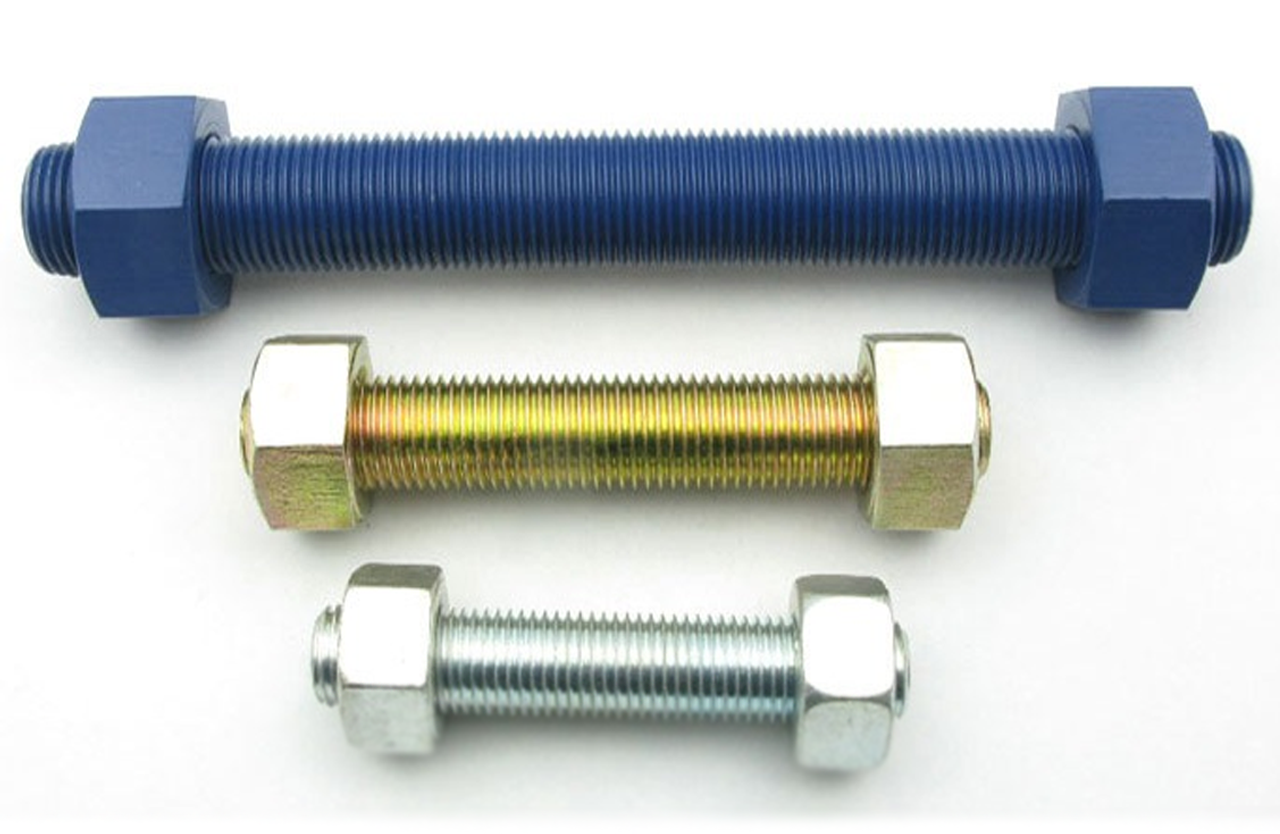

Fasteners

Explore Our Range of Industrial Fasteners

Fasteners are connections that are used to connect two parts or processes by the use of threading. The thread is incorporated into the appliance or system where it is used. It is generally very industrious and strong and cannot be easily removed unless used with a special device such as screw. In choosing a fastener it is very important to choose a fastener of the right material.

Different material fasteners have different advantages and disadvantages. Some may be suitable to certain environments while others may be vulnerable in those environments. It is important to choose the fastener you require according to the environment in which you choose to implement them to avoid the formation of corrosion in the fasteners.

Other Types of Fasteners

Nuts

- Wing Nuts

- T-Nuts

- Square Nuts

- Hex Nuts

- Lock Nuts

- Panel Nuts

- Flange Nuts

- Eye Nuts

- Dome Nuts

- Coupling Nuts

- Acron Nuts

Bolts

- U Bolt

- T Bolt

- Hex Bolt

- Hex Head Bolt

- Countersunk Bolt

- Eye Bolt

- Lag Bolt

Screws

- Anchor Screw

- Blind River

- Cotter Pin

- Concrete Screw

- Machine Screw

- Panel Screw

- Self Drilling Screw

- Socket Cap Screw

- Solid Rivet

- Spring PinSteel Lag Screw

- Steel Lag Screw

- Steel Set Screw

- Steel Shoulder Screw

- Threaded Rod

Washers

- Flat Washer

- Machine Washer

- Sealing Washer

- Slotted Washer

- Countersunk Bolt

- Split Washer

- Star Washer

Applications of Fasteners

Fasteners have various applications in:

- AirCraft Industry

- Submarines

- All Industries

- Commercial

- Home Appliances

- Vehicle Parts

Materials of Fasteners

We manufacture and supply Fasteners in the following steel material:

- Carbon Steel Fasteners

- Stainless Steel Fasteners

- Alloy Steel Fasteners

- Duplex Fasteners

- Super Duplex Fasteners

- Inconel Fasteners

- Hastelloy Fasteners

- Monel Fasteners

- Titanium Fasteners

- 254 SMO Fasteners

- Alloy 20 Fasteners

- Beryllium Copper Fasteners

- Cupronickel Fasteners

- Nitronic Fasteners

- Tantalum Fasteners

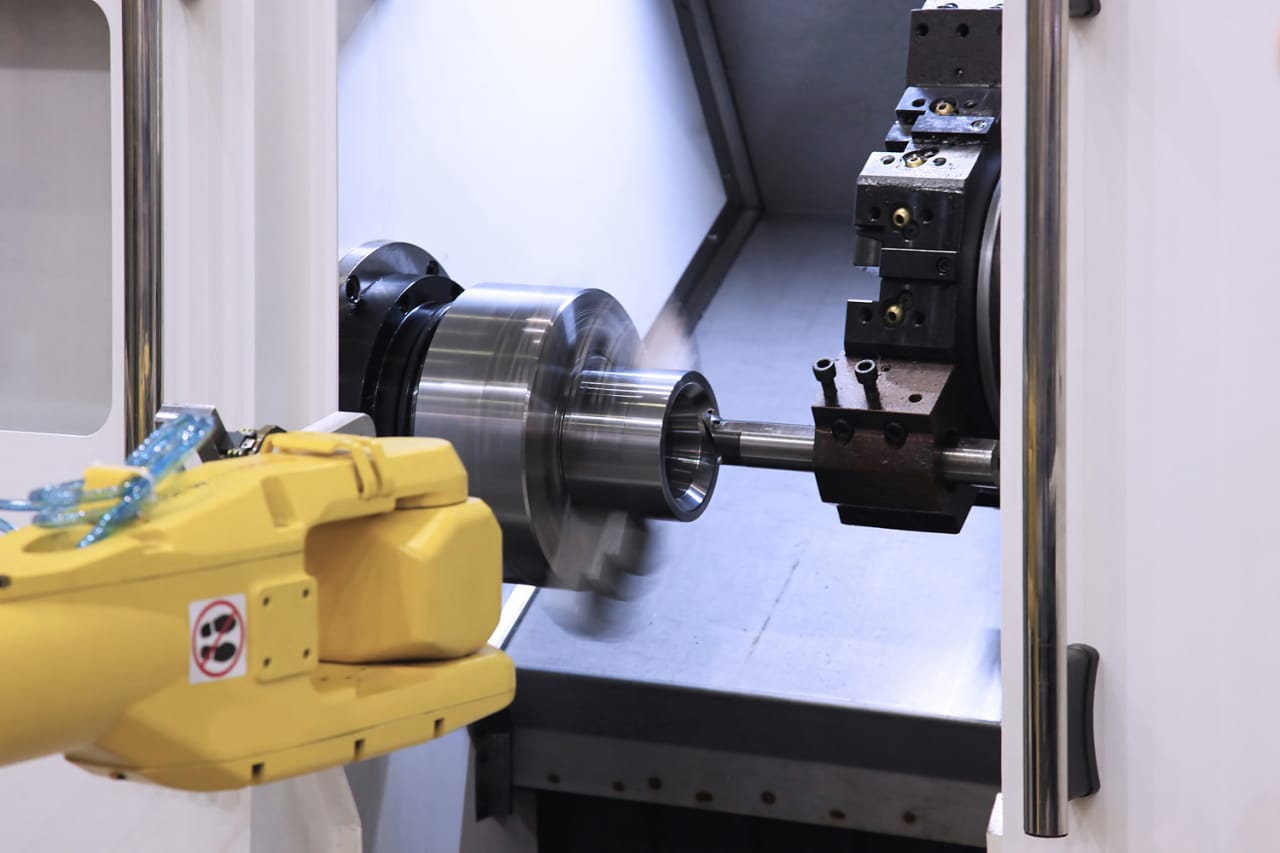

Production of Fastener

We have access to a state of the art mill facilities which run at a full capacity due to export order overload. We have __ heavy punch machines for shaping the fasteners. We also have threads machines to make NPT, BSPT & BSPP threads to the forging. Added to that we have in house testing facilities like spectro machine, PMI Machine, Mechanical test, Hardness Test, Ultrasonic Testing, Hydrostatic Testing, Pressure testing, and manual inspection of gauge. The production process can be divided separately for different type of fasteners:

Quality Control of Fasteners

Fasteners manufactured at Midland Alloys are backed by all world class certifications including ISO 9001:2008, ISO 14001:2004, OHSAS 18001:2007 & CE-PED 97/23/EC. We are also members of various renowned agencies and Chambers of Commerce including MASSMA, EEPC, FICCI, FIEO, Indian Merchants Chamber etc. We provide a 1 year product replacement warranty for all fasteners exported from our company.

We guarantee the quality because 100% Fasteners manufactured are checked in house for defects in quality and workmanship. Our quality program is a 3 layered independent department check for various factors including Dimensional Check, Visual Inspection, and Finishing, Burr level, Leakage Test, Pressure Rating test, Chemical inspection and Mechanical properties verification. We are running at full capacities and sometimes outsource our job due to increased workload

Packing and Documentation of Fasteners

Fasteners are packed in special and branded carton boxes and crates depending on the mode of transport. Fittings are wrapped with special nets to protect the threads.Ends are protected by plastic caps. They are then packed in the carton or wooden boxes.It is important that the damages in transit are avoided and pipe fittings reach the customer in the same form as it is manufactured. Thus we place lot of emphasis on packing and packaging of the goods.

Fasteners carry various export documents such as commercial invoice, packing list, Test Reports, HS Code, Country of Origin attested by chamber of commerce, Fumigation Certificate, Warranty Letter, and Base Material Certificates.

Each heat and lot of tube fittings is supplied with a material test certificate as per EN 10204 NACE 3.1 standards indicating the chemical and mechanical properties of the pipe fittings along with pressure rating. We also confirm the guarantee of the fittings supplied as per Purchase order specifications and attest the same in the Material Test Certificate. We also welcome any third party inspection from an agency nominated by the customer to comply with NACE 3.2 Certification if required by customer at an extra cost.Free samples in Stainless steel and carbons steel can be provided upon request to gauge quality and finishing of our fittings against confirmed receipt of purchase order. We can also send photos upon request.