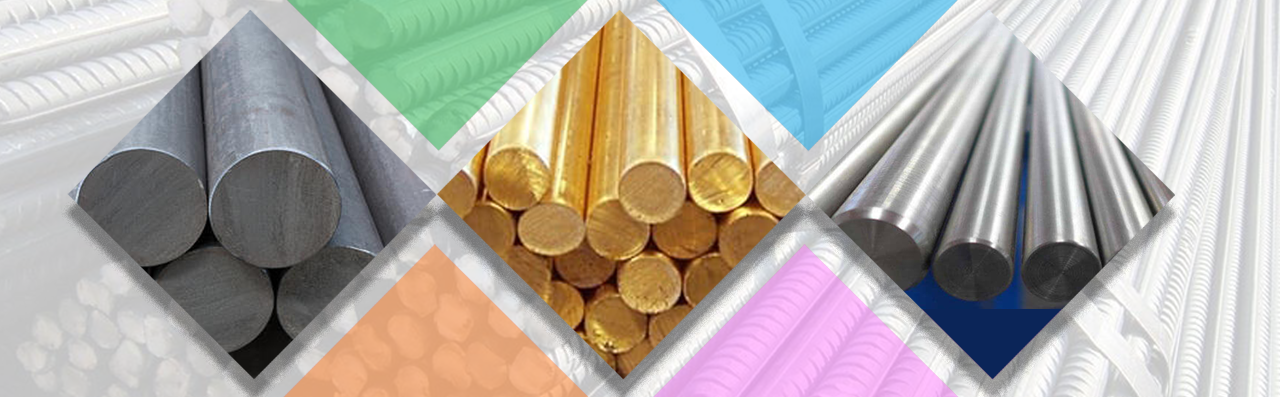

Bars

Application of Bars in Various Industries

- Oil & Gas

- Refineries

- Petrochemicals

- Research & Development

- Fabrication

- Pipeline

- Maintenance Of Projects

- Repairs

- Factories

Manufacturing Bars in Various Materials

- Carbon Steel Bars

- Stainless Steel Bars

- Alloy Steel Bars

- Duplex Steel Bars

- Super Duplex Steel Bars

- Inconel Bars

- Hastelloy Bars

- Monel Bars

- Titanium Bars

- Tantalum Bars

- SS904L Bars

- 254 SMOBars

- Incoloy Bars

- Alloy 20 Bars

- Nitronic Bars

- Cupronickel Bars

Quality of Bars

Steel Bar supplied by Midland Alloys are procured from A-Class mills around the world. We provide steel pipes of European, Japanese, Chinese and Indian origin. Our intelligent procurement system tracks real time prices of steel pipes and the available quantities in the industry as well as in stock. We are able to provide rock bottom prices to the customers with immediate delivery for small and major needs in standard sizes.

As a Steel bar supplier, Midland Alloys is backed by all the possible certifications of a world class mill including ISO 9001:2008, ISO 14001:2007, OHSAS 18001: 2004 & CE-PED 97/23/EC. We are also members of various renowned agencies and Chambers of Commerce including MASSMA, EEPC, FICCI, FIEO, Indian Merchants Chamber etc.

100% of steel pipes are checked in house for Surface Finish, Compliance to specifications as per ASTM Standards, Outer Diameter, Marking, Ends and Finishing. This ensures that we never face a rejection for the steel pipes supplied.

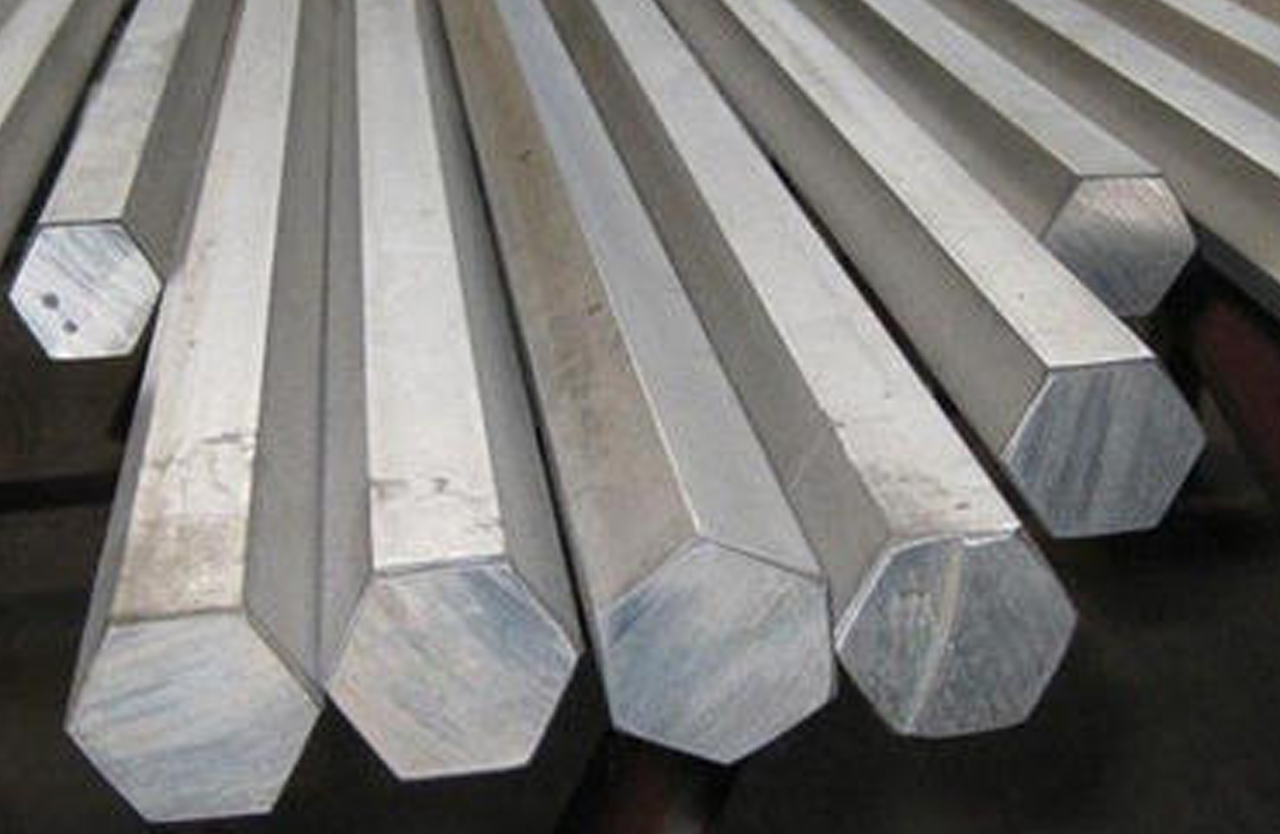

Production of Bars

We provide the following value addition to the pipes:

● Cut To Length: Steel bars can be supplied in full sizes or cut to length

as required by the clients.

● Polishing: Steel bars can be polished as required by clients. It can

also be provided in mill black finish if acceptable by clients.

● Heat Treatment: To change the mechanical properties of steel pipes

and make it suitable for some applications, steel pipes can also

undergo heat treatment process.

● Positive Material Identification: We have an in house PMI machine

to identify all the steel bars while arrival and dispatch so as the pipes

match to order specifications and client requirements

● Suggestions: We offer various suggestions and alternatives

depending on the client size and application requirements.

● Threading: We can also provide external threading to the steel bars,

in NPT, BSPT & BSPP threads if required by the clients.

Bars : Standards

The steel bars are marked in requirement of the International standards ASTM, AISI, JIS, BIS. with the format BRAND-SIZE-SPECIFICATION-GRADE-HEAT NUMBER-LOT NUMBER.

This format helps for identification of the Bars as well is supported with the Material Test Report. This is 100% traceable to the mill from which the material is procured.