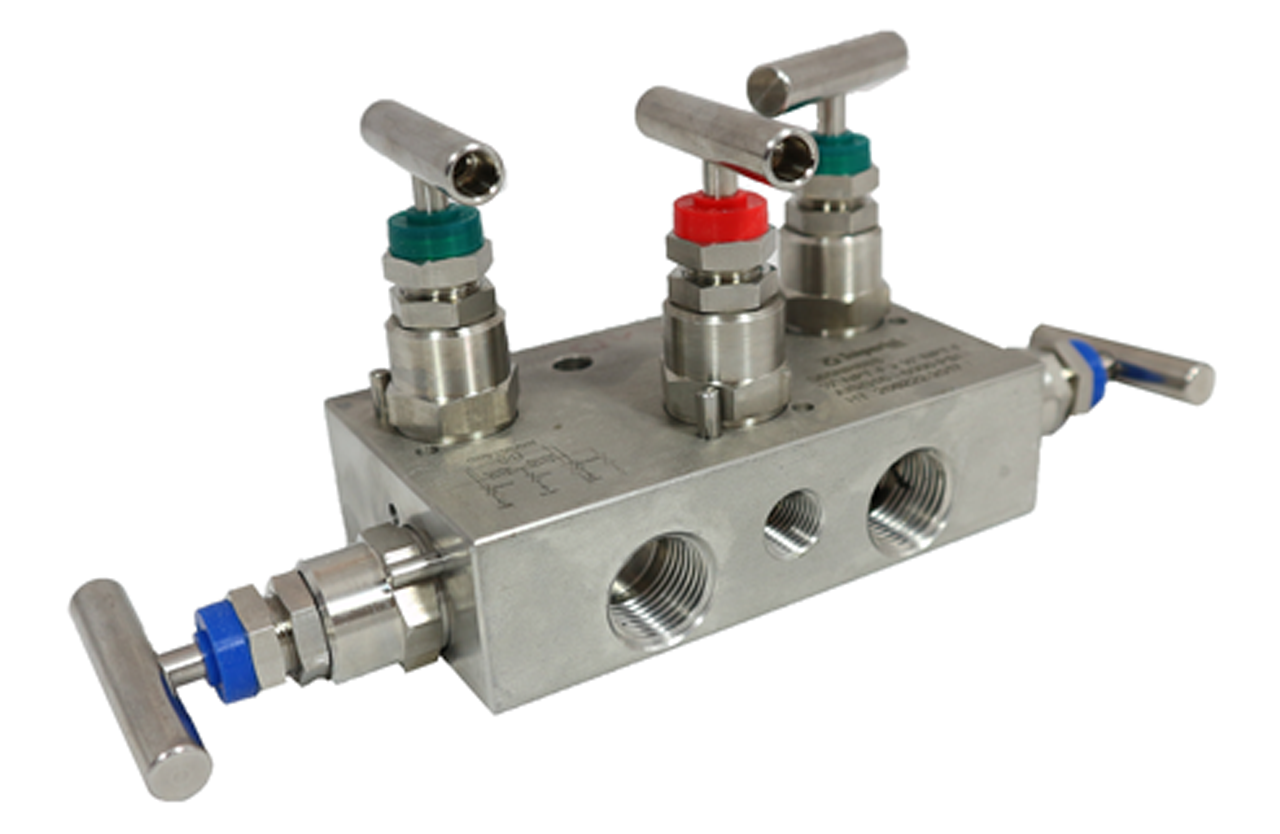

Valves

Components of a Valve System

Valve is a product that is used to provide a leak free connection between tubes and fittings for a seamless flow of liquids and gases. Valves are used in stopping and starting the flow and are also used to reduce or increase a flow and in controlling the direction of flow and regulating its process pressure.

Internally it consists of several parts depending on the type and application of the valve. Externally the nuts are crimped to the body with the use of ferrules. The ferrules are swaged to the tube. This is the reason for the seamless leakfree connection between the fitting and the tube.

Industries Using Midland Alloys Valves

- Hydraulics

- Pneumatics

- Instrumentation

- Calibration

- Oil & Gas

- Research & Development

Valves Available in Various Material

- Brass Valves

- Stainless Steel Valves

- Duplex Valves

- Super Duplex Valves

- Inconel Valves

- Hastelloy Valves

- Monel Valves

- Titanium Valves

- 254 SMO Valves

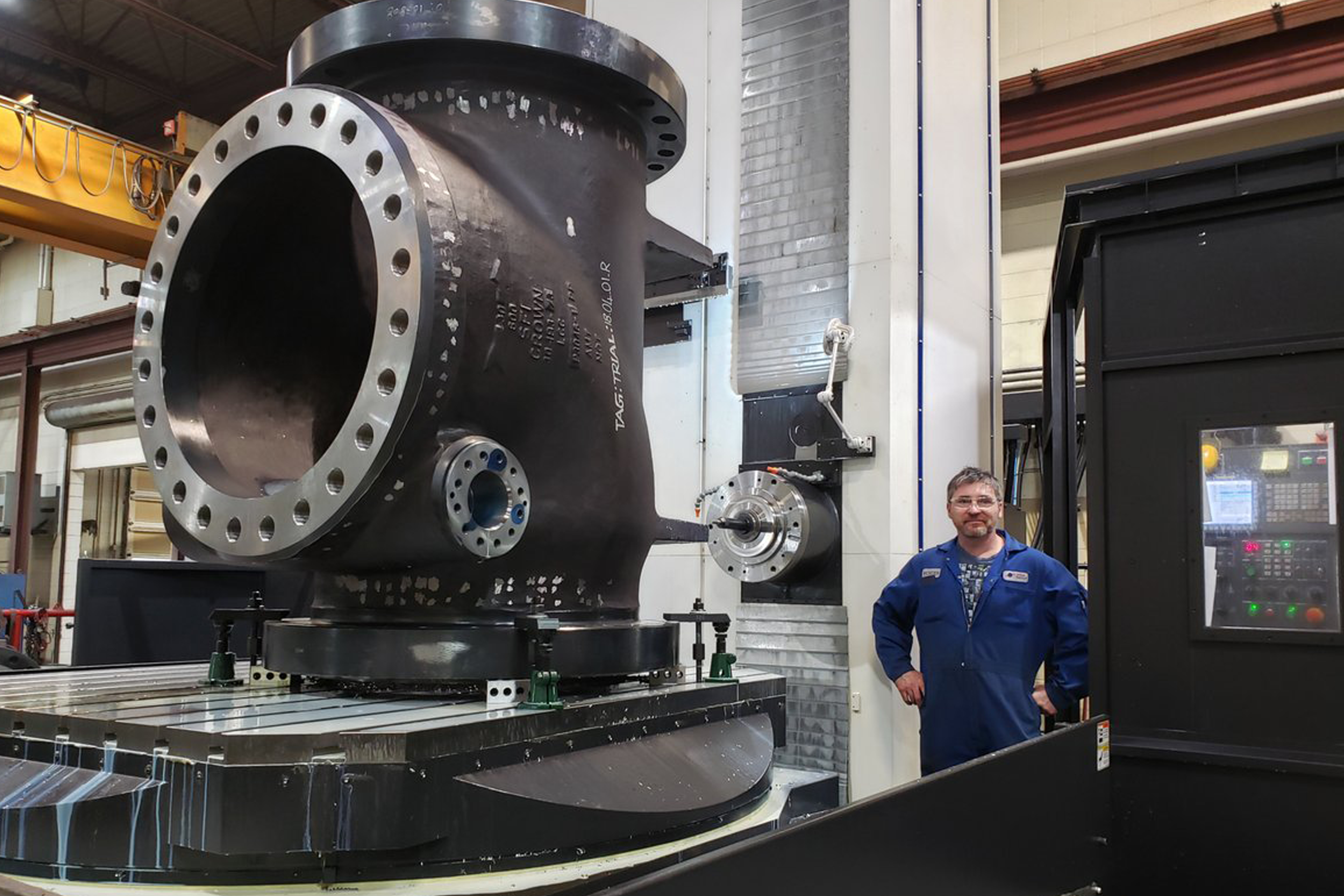

Production of Valves

Our state of the art factory has CNC Machines, Lathe Machines, Heavy Punch Machines, and Dye Machines for an end to end process at one place. Added to that we have in house testing facilities like spectro machine, PMI Machine, Mechanical test, Hardness Test, Ultrasonic Testing, Hydrostatic Testing, Pressure testing, and manual inspection of gauge.

Our production range also includes instrumentation valves, condensate pots, snubber, manifolds, and tube fittings Fittings can be made in NPT, BSPT & BSPP Threads. The production process can be divided for body, nuts and ferrules.